#ERP for small manufacturing business

Explore tagged Tumblr posts

Text

Overcoming Common Challenges in ERP Implementation for Manufacturing

In the dynamic and constantly changing environment of the industrial sector, enterprises must maintain flexibility and strive for competitiveness. Enterprise Resource Planning (ERP) software is a pivotal instrument that facilitates manufacturers in attaining their objectives. Enterprise Resource Planning (ERP) systems provide a broad range of integrated applications that are specifically developed to optimise operational processes, enhance productivity, and facilitate organisational expansion. Nevertheless, despite their considerable potential, ERP for manufacturing industry projects frequently encounter typical obstacles that can impede their achievement.

This blog post aims to examine the world of ERP for manufacturing industry, focusing on the most effective ERP solutions suitable for manufacturing enterprises of varying scales, encompassing both large-scale operations and small-scale organisations. Furthermore, we will explore the common challenges that manufacturers face during the adoption of the best ERP software for manufacturing companies and offer practical strategies for overcoming these difficulties.

The Power of ERP for Manufacturing:

Prior to delving into the complexities and remedies associated with the adoption of Enterprise Resource Planning (ERP), it is essential to comprehend the profound impact that ERP systems have on the manufacturing sector.

· ERP for Manufacturing Industry:

The manufacturing industry is characterised by intricate procedures, a wide range of product offerings, and complicated supply chain dynamics. Enterprise Resource Planning (ERP) demonstrates its exceptional capabilities in this context. Enterprise Resource Planning (ERP) systems for manufacturing encompass the integration of several operational tasks, such as production planning, inventory management, quality control, and finance management, under a unified and interconnected platform. The integration described herein provides manufacturers with the capability to access real-time visibility into their operations, hence facilitating data-driven decision-making and improving overall efficiency.

· Best ERP for Manufacturing Industry:

When it comes to the selection of ERP software for the manufacturing industry, it is imperative to carefully evaluate a system that is in line with the unique requirements of the organisation. Prominent enterprise resource planning (ERP) solutions catering to the manufacturing industry encompass SAP S/4HANA, Oracle ERP Cloud, Microsoft Dynamics 365, and STERP by Shanti Technology. These solutions provide comprehensive functionalities specifically designed for manufacturing processes, enabling organisations to enhance production efficiency, minimise expenses, and enhance overall profitability.

· ERP for Small Manufacturing Businesses:

Enterprise Resource Planning (ERP) systems are not exclusively designed for huge organisations but can also be beneficial for small manufacturing businesses. ERP systems can provide significant advantages to small manufacturing enterprises as well. Indeed, the implementation of an appropriate Enterprise Resource Planning (ERP) solution can effectively equalise the competitive landscape for small-scale firms, equipping them with the necessary resources to compete efficiently. Scalable choices, such as Shanti Technology's STERP, present themselves as suitable solutions for small enterprises seeking expansion opportunities.

Challenges in ERP Implementation for Manufacturing:

Although the potential benefits of Enterprise Resource Planning (ERP) are alluring, the process of deploying such systems might be perceived as a formidable endeavour accompanied by several obstacles. Manufacturers frequently encounter several challenges in their operations.

· Resistance to Change:

Resistance to change is a prominent obstacle encountered with the adoption of Enterprise Resource Planning (ERP) systems. There may exist a certain degree of resistance among employees who have become accustomed to utilising legacy systems over an extended period of time, hence exhibiting hesitancy towards embracing novel technological advancements. In order to surmount this problem, it is imperative to engage employees from the inception, effectively communicate the advantages of Enterprise Resource Planning (ERP), and offer thorough training and assistance.

· Data Migration:

The process of data migration is often characterised by its complexity and time-intensive nature. The process of migrating data from outdated legacy systems to a modern Enterprise Resource Planning (ERP) system has the potential to result in errors and compromise the integrity of the transferred data. The rigorous planning, validation of data accuracy, and implementation of a comprehensive data migration strategy are crucial.

· Integration Issues:

The effectiveness of ERP systems relies on their ability to smoothly integrate with other software and systems utilised inside the organisation. The integration process may encounter difficulties when preexisting systems lack compatibility with the newly implemented Enterprise Resource Planning (ERP) system. Conducting a comprehensive compatibility study and making necessary investments in middleware are critical measures to ensure seamless integration.

· Budget Overruns:

Budget overruns are a common occurrence in Enterprise Resource Planning (ERP) implementations, mostly attributed to unanticipated expenditures such as customisation, supplementary training, or prolonged project schedules. In order to address the issue of budget overruns, it is advisable to develop a comprehensive budget plan, including provisions for unforeseen circumstances, and maintain vigilant oversight of expenditures during the execution phase.

Overcoming ERP Implementation Challenges:

· Change Management:

In order to mitigate resistance towards change, it is imperative to involve employees at an early stage of the process. Organise seminars, facilitate training sessions and effectively articulate the advantages of the Enterprise Resource Planning (ERP) system. Promote the solicitation of feedback and implement necessary modifications in accordance with user input. Resistance to the implementation of the best ERP software for manufacturing company tends to decrease when employees perceive the system's usefulness and receive enough support during the transition process.

· Data Migration Strategy:

The effectiveness of data migration is contingent upon thorough planning and precise implementation. Establish a data migration team tasked with the responsibilities of data cleansing, validation, and mapping. It is advisable to conduct testing of data migration procedures inside a controlled setting prior to executing the implementation on a larger scale. It is imperative to consistently perform data backups in order to safeguard data integrity throughout the transfer process.

· Integration Expertise:

In order to address integration difficulties, it is advisable to engage in collaboration with ERP suppliers and IT professionals who possess specialised knowledge and skills in the field of integration. These individuals possess the ability to identify possible challenges related to integration and devise appropriate strategies to address them. It is advisable to explore the option of investing in middleware or connectors that can effectively facilitate the integration process between the Enterprise Resource Planning (ERP) system and the pre-existing systems.

· Budget Management:

In order to mitigate the occurrence of budget overruns, it is advisable to design a budget that is grounded in realism and includes a contingency fund. It is advisable to conduct periodic evaluations of expenditures and make necessary modifications to the budget accordingly. It is advisable to give precedence to fundamental customization and supplementary components while postponing non-essential functionalities to subsequent stages of the implementation process. The implementation of a staged approach can effectively manage expenses while also guaranteeing the establishment of essential functionality.

Leveraging STERP for Manufacturing Company:

In the context of addressing the obstacles encountered during ERP adoption, it is vital to underscore the potential value that Shanti Technology's STERP solution holds for manufacturers.

· STERP's Manufacturing Expertise:

The manufacturing expertise of STERP is highly regarded as it is an ERP solution that has been specifically tailored to meet the needs of the manufacturing industry. The software provides a variety of functionalities specifically designed for manufacturing operations, including but not limited to demand prediction, production scheduling, and quality management. The industry-specific experience of STERP facilitates the deployment process and guarantees a seamless alignment between your ERP system and your manufacturing requirements.

· Scalability for Small Manufacturers:

Scalability is a crucial aspect for small manufacturers, and it has been observed that the Small Manufacturer Enterprise Resource Planning (STERP) system offers a viable solution in this regard. As an enterprise expands, the Scalable Technology and Enterprise Resource Planning (STERP) system may effectively meet the increasing requirements, so serving as a favourable option for organisations seeking efficient scalability without the necessity of investing in a new Enterprise Resource Planning (ERP) system in the future.

· Comprehensive Training and Support:

STERP provides a comprehensive training and support programme aimed at facilitating a seamless changeover process. STERP offers a comprehensive range of services, including on-site training sessions and round-the-clock customer support, to ensure that your staff is adequately equipped to maximise the efficiency and effectiveness of the ERP system.

Final Thoughts:

The deployment of Enterprise Resource Planning (ERP) systems in the manufacturing business presents several difficulties. However, by employing appropriate techniques and utilising the best ERP software for manufacturing companies, developed by STERP (Shanti Technology), these issues can be effectively addressed. Manufacturers can optimise the utilisation of ERP systems by effectively handling resistance to change, methodically preparing data migration, managing integration processes efficiently, and maintaining strict adherence to budgetary considerations.

It is important to acknowledge that the adoption of Enterprise Resource Planning (ERP) systems should not be viewed as a singular occurrence, but rather as a continuous endeavour aimed at achieving optimal performance. It is imperative to consistently evaluate the performance of your Enterprise Resource Planning (ERP) system, solicit input from users, and remain abreast of prevailing industry standards in order to ascertain that your ERP system is capable of efficiently supporting your manufacturing activities.

The STERP system represents an optimal enterprise resource planning (ERP) solution specifically designed for the manufacturing sector. It provides customised functionalities, scalability, and comprehensive assistance to enable firms to excel in a highly competitive market. Manufacturers can achieve operational streamlining, enhanced efficiency, and long-term success in the ever-changing industrial landscape by making informed decisions on the selection of an appropriate Enterprise Resource Planning (ERP) solution according to established implementation best practices.

#ERP for manufacturing industry#Best ERP for manufacturing industry#ERP for small manufacturing business#Best ERP software for manufacturing#Manufacturing software for small business#Best ERP for small manufacturing business#ERP software for manufacturing industry#ERP for manufacturing company

7 notes

·

View notes

Text

#erp software#cloud erp#erp application#erp consulting services#erp development company#erp development services#erp for small business#erp system#erp integration#crm software#erp for manufacturing

1 note

·

View note

Text

Make manufacturing simple with SAP Business One Cloud! 🌟 Plan and track your work, check for missing materials, and keep everything running smoothly. It's like having a smart helper to make sure you finish on time and save money too

#sap b1#cloud erp#sap erp#clouderp#sap business one#erpsolutions#erp software#erp for small business#sapbusinessone#cloud partner#manufacturing erp#manufacturing industries#manufacturing erp software#manufacturing with netsuite#services#industry#industries#manufacturing supply company#warehouse#development#manufacturing consent

0 notes

Text

#technews#Enterprise Resource Planning (ERP)#ERP Solutions#Business Management Software#Integrated Business Applications#Supply Chain Management#Customer Relationship Management (CRM)#Financial Management Systems#Human Resources Management#Inventory Management Software#Manufacturing Resource Planning#Cloud ERP Solutions#On-Premise ERP Systems#ERP Implementation Services#ERP Consulting#ERP Software for Small Business#ERP Software for Manufacturing#ERP System Integration#ERP Software Development#ERP Customization Services#ERP Training and Support

0 notes

Text

Zillancer: Best Manufacturing ERP for Small Businesses

Small businesses in the manufacturing sector can now achieve better efficiency with ERP software solutions. Zillancer connects you with expert freelancers to help integrate customized ERP systems that simplify your processes, boost productivity, and foster growth. Get your manufacturing operations running smoothly with our tailored ERP solutions.

#Best ERP for Manufacturing#Best ERP for Small Manufacturing Business#Best ERP for Manufacturing Industry#Top 10 Manufacturing ERP Systems#Best Cloud ERP for Manufacturing#Manufacturing ERP#Manufacturing ERP for Small Business#Best ERP Systems for Manufacturing#ERP for Manufacturing Industry#ERP System for Small Manufacturing#Top 10 ERP Software for Manufacturing#ERP for Custom Manufacturing#Top ERP for Manufacturing#Cloud Based ERP for Manufacturing#ERP for Manufacturing Companies#ERP Manufacturing Module#ONEERP#Microsoft Dynamics 365#Microsoft Dynamics Business Central

0 notes

Text

Low-Cost ERP for Small Businesses in India

ERP for Small Businesses

With the firms today seeking to reduce costs while at the same time expanding in the emerging and competitive market structure in India, small businesses are no exception. For purposes of this paper, Enterprise Resource Planning (ERP) systems that used to be available to only large organizations have become relevant systems for small enterprises. This blog goes beyond merely explaining low-cost ERP adoption for small businesses in India, and extends into how these solutions are helping manufacturing and other industries successfully.

Understanding ERP for Small Businesses in India

ERP systems facilitate the management of organizational operations since several fundamental business processes are bundled in this system. The two major factors that small businesses in India have been facing have always been cost and sophistication. Of course, these concerns are mitigated by low cost ERP solutions which provide relatively easy to integrate solutions more specifically configured to address the requirements of SMBs. They help in organizing inventories, accounts, and supply chains and bring efficiency for the business owners to make right decisions.

Digitalization is on the rise in India through government adoption of ideologies such as “Digital India” which has encouraged small enterprises to adopt ERP systems.

Purchasing a low cost, today’s ERP software directs itself to a particular area of specialization such as manufacturing or retail or service industries, etc., so that it offers appropriate features for meeting corporate needs for efficient operations.

Why Choose Low-Cost ERP for Small Business Manufacturing?

Small business manufacturing is generally characterized by very low profit margins which makes proper resource utilization compulsory. Affordable ERP systems can integrate repetitive functions, provide resource tracking and control production scheduling for the manufacturing industry. It also offers affordable operation thus increasing overall organizational efficiency.

For instance, when choosing the software for small business manufacturing ERP systems might contain production planning, quality control, inventory modules among others.Furthermore, such software enables corporations to satisfy the client requirements faster and enhance the loyalty of clients.

As for the small businesses in India, the growth of ERP has the advantage of entrance in small scale, big in process. This adaptability also means that manufacturers do not have to incorporate a lot of unwanted aspects in their products, which holds initial implementation costs in check.

The Role of Manufacturing Software for Small Business Growth

Software that supports manufacturing for small businesses is one of the industrial solutions that is crucial to companies’ development as it provides the solution for substantial operational issues.This do not create bottlenecks and also nurtures health culture or work and efficiencies.

Manufacturing software describes some aspects of automation and effective communication programmes for managing work flow, production of reports and approximations within production departments. They also assist small manufactures in coordinating organizational activities with business goals in order to retain flexibility. Moreover, requirements of industries are easier to meet because most ERP systems contain modules, which correspond to legal demands.

Truly for the small business in India, the investment made in the manufacturing software is about creating a platform for future growth. Substituting current standard activities for activities that can be more efficiently accomplished through the use of technology can free up an entrepreneur’s time to develop new and well-thought-out ideas to penetrate growing markets in an ever-competitive world.

Cost-Effective ERP Solutions: Breaking the Accessibility Barrier

One of the reasons that forced many small businesses to slow down or completely drop the implementation plans is the notion that ERP systems are very costly. But low-cost ERP for the Indian small business is gradually turning the tide. The traditional key operations, including finance, inventory, and customer relationship management, can now be performed by affordable solutions.

Such affordability is further enhanced by the emergence of the new cloud-based ERP systems. Cloud ERP is also more affordable than other on-premise systems since they don’t require an enormous capital investment as customers purchase a license but pay for the software service instead. This allows even the start up businesses to adopt the advanced technology hence be able to enjoy the fruits of mechanized business entities.

Moreover, availability in service packages is also a frequent strategy with ERP for small business manufacturing vendors. These solutions mean that businesses only pay for the extras which in turn make it possible for them to be both practical and affordable.

ERP for Small Business in India: Overcoming Implementation Challenges

Of course there are a number of advantages that can be accredited to the implementation of ERP systems however the process is not without its issues for small businesses especially. The challenges which people may face include lack of technical knowledge, reluctance to change, and financial problems. But all the above challenges can be avoided if the right low-cost ERP provider is selected.

Every experienced vendor offering ERP solutions for small businesses in India guarantees the intuitive interface, extensive training for users, and efficient support service. This makes sure that organizations can easily implement an ERP system without facing a lot of problems.

The Evolution of ERP Systems for Indian Small Businesses

Once ERPs were large and costly systems today they are relatively more versatile, easier to implement tools that define small business needs. In particular, the change of this type is very suitable for the Indian conditions, for the Calderon – MSMEs which forms the financial foundations of the country’s economy. The various inexpensive erp systems in the market for small businesses are especially developed to solve some problems like less capital, lag of professional personnel, and inadequate resources.

Software for manufacturing and as a part of the ERP suite has been a boon for small businesses. These tools focus on the needs of production based small organizations through the provision of tools such as production, inventory, and quality control. Localized solutions mean that there is superior business erb for Indian small businesses since the solutions can be configured to meet specific industry needs and other compliance.

ERP’s adoption also happens simultaneously with India’s digital drive as well as the worthy causes such as ‘ Digital India’ and ‘Make in India’ to impel small enterprises to go for technology improvements.

Key Features of ERP for Small Business Manufacturing

ERP for small business manufacturing brings concern to improve and optimize manufacturing processes and flows. There is the inventory feature for instance, which assists the business to manage its stock well so that it does not end up with either of the two problems, a scarce stock or surplus stock. Production scheduling is also an important element; the manufacturing processes are organized between supply chain members and timeframes are respected.

Main quality management tools that are integrated in the ERP systems for developing small business manufacturing enable organizations to achieve quality standards and control on defects. This they achieve for the purpose of developing customer confidence and for compliance to the set standard. Sometimes, these systems also provide modules for equipment maintenance so that potential downtime could be minimized, and productivity could be improved.

They also include real decisions that ERP for small businesses, we get real time business analysis which helps the manufactures in removing bottlenecks in the business process repeatedly. Through these features, small enterprises will thus be able to hold their own against massive enterprises with relatively lower costs.

Benefits of ERP for Small Businesses in India

Consequently, the implementation of ERP for small business in India has many advantages such as increased organizational efficiency, management of finance and better decision making. By having all the vital business information contained in one place, business owners are fully aware of their business happening. This helps them be able to see areas in the chain that are costly and working on a way to increase its profits.

To specific sectors of manufacturing businesses being the small businesses, the benefits of ERP are unique in that it offers them efficiency in production and minimizes wastage. All these advantages are relevant especially with regard to the Indian conditions, as most of small businesses are close to marginal. Besides, cheap ERP solutions allow companies to cut down on manual entries further decreasing the risks of mistakes and time consumption.

Another important benefit of the contemporary ERP systems is their scalability. Small businesses can start common modules and later expand to other advanced modules. Such flexibility keeps ERP for small business viable in the long term and affordable for any business that is planning for growth in the near future

Choosing the Right ERP for Small Businesses in India

Choosing the proper ERP means determining what your company requires, specifically for the organization. For example, small business manufacturing firms would be reasonable and rational incurable in special production planning and inventory management elements. On the other hand, enterprises that are more focused on the retail side may find sales and customer relationship management modules relevant of higher importance.

The availability and comparatively low cost of ERP solutions for small business in India is the other factor. SaaS ERP solutions have therefore developed as a new trend of service where Organizations subscribe to the service provided by the ERP software developers at a fee while incurring less costs for hardware and infrastructure than in the traditional on premise solutions. These systems are also relatively easy to integrate into workplace practices and less resource demanding in terms of maintenance thus suitable for organizations, particularly the small business types, with inadequate information technology support.

Any ERP selection should fit into your organization needs and should be scalable for future. Thus, when oriented on such factors, small businesses can identify efficient ERP solutions which will cost less while being useful.

Challenges in Implementing Odoo Erp Software for Small and Medium Businesses

ERP systems have many advantages that include improved organizational efficiency Most executives, however, will agree that the implementation of Odoo Erp Software for Small and Medium Businesses is not without its problems. ERP implementation may be expensive even with inexpensive ERP solutions, and this is one of the biggest challenges. Small businesses in India, especially the new ones, face a major challenge in that they are able to allocate a big chunk of their capital to software implementation and training.

The next problem is the absence of qualified personnel in the companies’ staff – personnel who focused mainly on fostering technical competencies. Learning from ERP systems may be a new concept that small business owners and employees may not have come across before thereby requiring them to go through a steep learning curve. Furthermore, ERP integration with other systems may also be challenging because the existing manufacturing software for small businesses need interfaces for equipment and machinery.

However, when implementing ERP systems, there are major challenges that an organization is bound to meet in the initial stages of its implementation but the benefits are longer term and outweigh the challenges.

The Role of Cloud Technology in ERP for Small Businesses

As a result of the technological advancements in cloud computing, ERP for small businesses in India has shifted greatly and become more affordable. Unlike the conventional ERP systems that called for major investment in hardware as well as other supporting structures, most of the cloud-based ERP systems work on the idea of licenses. This does not require the business organization to invest heavily at the start which is common in cases that require large capital investment, sm Bundy Hence making the decision easy for the small business organizations to implement.

Cloud ERP systems also come without flexibility that is difficult to match in other systems. This helps business owners have easy access to their data without having to go to the business premise, allowing people to work from the comfort of their homes, use current data to make decisions or timely interventions. This is especially useful in small business manufacturing where most of the managerial personnel will be using the system to oversee production lines from different places.

Another thing is that cloud ERP systems are built to easily expand downward or upward when needed. This way, new features could easily be incorporated as a business evolves, without necessarily having to parlay the whole system. This also guarantees that ERP for small businesses is a sustainable solution, one that can help sustainable growth.

Future Trends in ERP for Small Business Manufacturing

This paper discusses how new technologies and changing business trends determine the future of ERP for small business manufacturing industries in India. Enterprise resource planning (ERP) is one of the most important technological trends in modern business, the development of which will be significantly influenced by artificial intelligence and machine learning. These technologies allow for accurate decisions to be made in order to predict and therefore stay ahead of the market.

Another interesting trend is the connection of the Internet of Things (IoT) with ERP software programs. Real time data from equipment, stocks and production processes is achievable through use of IoT devices which can improve manufacturing software for small businesses.

Customization will also increase as ERP providers will provide special designed solutions according to the need and demand of small business in India only. This means that ERP systems stay relevant and pertinent in today’s ever changing business world.

Transforming Small Businesses with Affordable ERP

ERP for small business entities has become more of a necessity than luxury in India. The solutions are flexible for any company size and prerequisites that allow even small businesses to gain a competitive advantage by applying the features of advanced technologies.

In the case of small business manufacturing, it becomes easier because the use of ERP systems turn out to be very vital especially in boosting efficiency, conformity and quality. Through the above solutions, the small business can be at par with the large business and even succeed in the modern business environment.

Over time, available and advanced ERP systems will enhance as advances in technology progresses. This therefore poses a chance to India’s small business to consider developing strategies in embracing digital transformation in their business operations in a bid to post sustainable growth of their businesses.

0 notes

Text

#sales and distribution module in erp#erp software#erp manufacturing#accounting#erp solution bd#crm software#india#erp360#fnb360#erp software for construction industry#erp for manufacturing industry#manufacturing erp#erp software for manufacturing industry#manufacturing erp software#manufacturing software small business#manufacturing software

0 notes

Text

ERP for small business

Implementing an ERP system for your small business can be a game-changer, propelling your operations to new heights of efficiency and productivity. While traditionally associated with large corporations, ERP solutions are now tailored to meet the unique needs of small businesses, offering scalable and affordable options. By centralizing your data and streamlining processes across departments, an ERP system can eliminate redundancies, reduce errors, and provide real-time insights into your business performance.

This comprehensive approach allows you to make informed decisions quickly, adapt to market changes, and stay ahead of the competition. Moreover, as your business grows, an ERP system can easily accommodate your expanding needs, ensuring a smooth transition without the need for disruptive overhauls. Investing in ERP for small business isn't just about keeping up with technology; it's about positioning your company for sustainable growth and long-term success in an increasingly competitive marketplace.

Click here to Know More:https://www.intelegain.com/top-15-erp-systems-for-small-businesses/

0 notes

Text

Emerging ERP Trends Shaping the Future in 2024

In today’s fast-paced business environment, Enterprise Resource Planning (ERP) systems have become essential for streamlining operations and providing a unified approach to managing various company processes. As we navigate through 2024, several key trends are transforming the ERP landscape, reflecting the ongoing technological advancements and evolving business needs.

Augmented Financial Efficiency:

SAP ERP solutions are becoming increasingly vital across diverse industries. These systems not only provide valuable insights into profitability, revenue, and cost but also incorporate advanced forecasting and predictive analytics. By leveraging machine learning algorithms, modern ERP systems can analyze historical financial data to offer precise predictions and recommendations, enhancing decision-making processes.

Cloud-First Approach:

The shift towards cloud-based ERP solutions is driven by their robust security, flexibility, and scalability. The subscription-based model associated with cloud ERP systems offers cost-effectiveness while facilitating real-time collaboration among teams spread across different locations. These systems also provide easy integration with various applications and ensure seamless upgrades.

Mobile ERP Solutions:

Mobile ERP applications have gained prominence due to their accessibility and functionality. They simplify tasks such as expense reporting, workflow approvals, and performance monitoring. The optimized user interfaces for various devices ensure a consistent experience across smartphones, tablets, and desktops, making ERP systems more versatile and user-friendly.

Integration of Machine Learning and AI:

Machine learning and artificial intelligence are now integral to ERP systems, enhancing capabilities such as fraud detection, predictive maintenance, and customer segmentation. Natural language processing features enable users to interact with ERP systems using chatbots and voice commands, streamlining queries and data entry processes.

IoT Integration:

The incorporation of the Internet of Things (IoT) into SAP ERP systems allows for real-time monitoring of assets like vehicles and equipment. This integration facilitates optimized resource utilization and proactive maintenance by analyzing data to identify inefficiencies and automate necessary actions.

Enhanced Security Measures:

Advanced encryption techniques, anomaly detection algorithms, and multi-factor authentication are crucial for safeguarding sensitive data within ERP systems. Regular security audits and continuous monitoring help ensure compliance with industry standards, offering a secure platform for businesses.

Focus on ESG and Sustainability:

SAP ERP modules now emphasize sustainability management, tracking key performance indicators related to carbon emissions, waste generation, energy consumption, and social responsibility. These analytical tools provide insights into the environmental and social impacts of business operations, supporting data-driven sustainability initiatives.

Quantum Computing and Blockchain:

Blockchain technology enhances transparency and traceability in transactions, particularly in sectors with complex regulatory demands and supply chains. Meanwhile, quantum computing promises faster data processing and improved encryption, potentially boosting the performance and security of ERP systems.

Broadening Operational Scope:

Modern ERP systems are expanding to integrate with third-party services and applications, supporting comprehensive end-to-end business processes. Integration of modules like customer relationship management, supply chain management, and business intelligence provides a unified view of organizational operations and performance metrics.

Conclusion:

In summary, these evolving ERP trends for 2024 illustrate the rapid advancements in technology and their impact on business operations. Companies that embrace these innovations will benefit from increased efficiency, adaptability, and improved decision-making. For organizations seeking to implement these latest trends, Cogniscient offers specialized ERP solutions tailored to meet specific needs and goals.

#SAP Business One#SAP B1#SAP Business One Partner in India#ERP for Manufacturing Industry#SAP ERP for Small Businesses#Best ERP software company in India#ERP Solutions Provider in India

0 notes

Text

SAP Business One Gold Partner Noida |Delhi |Gurgaon| Ghaziabad India

Elevate your interior decor and furniture manufacturing business with SAP Business One Take control of your success

Trusted SAP Business One Gold Partner with 500+ Successful Implementations including Kanpur, Jaipur, Lucknow, Ludhiana, Manesar, Indore, Pune, Mumbai, Kolkata, Faridabad, Sonipat, Raipur, Ambala Etc.

#SAP Business One#SAP B1#SAP Business One Partner in India#ERP for Manufacturing Industry#SAP ERP for Small Businesses#SAP ERP for Food & Beverages#Best ERP software company in India#ERP Solutions Provider in India#Best ERP Software in India

0 notes

Text

🏆 India Wins the World Cup! 🌟🏏 Just as our cricket heroes triumphed through challenges, Nova Technosys empowers businesses to rise above competition with Tally products and customized ERP solutions. Optimize your operations and score big in your industry! 🌐✨ #WorldCupChampions #NovaTechnosys #TallySolutions #ERP #BusinessGrowth #SuccessJourney

#accounting#world champion#icct20worldcup2024#tallyproducts#erp software#custom erp software development#small business#manufacturer#cloud erp#business#erp solution

0 notes

Text

Maximizing Operational Efficiency: How ERP Software Benefits Manufacturing Companies

Efficiency and precision are of utmost importance in the ever-evolving world of manufacturing. Manufacturers consistently strive to optimise operational efficiency, minimise expenses, and enhance the quality of their products. The utilisation of Enterprise Resource Planning (ERP) software has been identified as a transformative factor within the manufacturing industry. This article examines the advantages of ERP software and provides an analysis of the most suitable ERP solutions for manufacturing enterprises.

· The Manufacturing Challenge:

Manufacturing enterprises encounter the formidable task of effectively managing intricate and interdependent operational processes. The pursuit of efficiency is an ongoing objective across various domains, ranging from supply chain management to production planning.

· What is ERP for Manufacturing?

ERP for manufacturing company is a comprehensive system that facilitates the integration and optimisation of several business activities inside a manufacturing organisation. The platform offers a centralised solution for the management of data and facilitates the process of decision-making.

· Best ERP for Manufacturing:

Selecting the optimal Enterprise Resource Planning (ERP) system holds paramount importance for manufacturing enterprises. The optimal Enterprise Resource Planning (ERP) system for manufacturing is contingent upon its ability to harmonise with the distinct requirements and objectives of the organisation. Important considerations encompass scalability, industry-specific capabilities, and user-friendliness.

· Streamlined Operations:

Enterprise Resource Planning (ERP) solutions serve the purpose of integrating a wide range of activities, encompassing inventory management, production scheduling, order processing, and quality control. The process of streamlining mentioned above serves to decrease the need for manual data entry, mitigate the occurrence of errors, and expedite the progression of workflows.

· Real-time Data Access:

Real-time data access is a key feature offered by manufacturing Enterprise Resource Planning (ERP) systems. These systems allow decision-makers to have immediate visibility into vital data, including production status, inventory levels, and financial performance. The ability to access information immediately enhances the capacity for well-informed and prompt decision-making.

· Enhanced Supply Chain Management:

The optimisation of supply chain management plays a crucial role in ensuring the success of manufacturing operations. Enterprise Resource Planning (ERP) software enhances the efficiency of the supply chain through the enhancement of demand forecasting, inventory control, and supplier relationships.

· Production Planning and Scheduling:

The inclusion of advanced production planning and scheduling technologies within the realm of Enterprise Resource Planning (ERP) for manufacturing is a notable aspect. These skills empower firms to optimise their manufacturing processes, effectively allocate resources, and successfully meet delivery dates.

· Quality Control and Compliance:

Ensuring the preservation of product quality and adherence to regulatory standards is an imperative aspect of the production process that cannot be compromised. Enterprise Resource Planning (ERP) systems play a crucial role in enabling quality control processes through their ability to monitor and manage product requirements, conduct inspections, and handle documentation.

· Cost Reduction:

Cost reduction can be achieved through the utilisation of Enterprise Resource Planning (ERP) software. This software facilitates the identification of potential cost-saving possibilities by thoroughly analysing data and optimising the allocation of resources. Manufacturers have the potential to mitigate waste, exercise cost management, and augment their profitability.

· Scalability and Growth:

Scalability and growth are key considerations when selecting an enterprise resource planning (ERP) system for manufacturing. It is imperative to choose an ERP solution that can effectively accommodate the expanding needs of the organisation over time. Scalable enterprise resource planning (ERP) systems provide the capability to support organisational growth and effectively respond to evolving market dynamics, hence providing sustained value over an extended period of time.

Final Thoughts:

The utilisation of Enterprise Resource Planning (ERP) software has become an essential asset for manufacturing organisations aiming to optimise operational efficiency. The optimal manufacturing ERP system is one that effectively corresponds to the specific requirements of the organisation, hence enhancing operational efficiency, facilitating instantaneous data retrieval, and optimising the supply chain.

Manufacturers can achieve a competitive advantage, cost reduction, and long-term growth in a dynamic market by making investments in Enterprise Resource Planning (ERP) systems. The ongoing evolution of manufacturing necessitates the utilisation of ERP software as a fundamental element for achieving success. This software empowers organisations to effectively navigate the complexities and prospects presented by the contemporary marketplace, instilling them with a sense of assurance.

#ERP for manufacturing industry#Best ERP for manufacturing industry#ERP for small manufacturing business#Best ERP software for manufacturing#Manufacturing software for small business#Best ERP for small manufacturing business#ERP software for manufacturing industry#ERP for manufacturing company

6 notes

·

View notes

Text

Best ERP for Small Manufacturing Business in India

ZipERP is the best ERP software for the small manufacturing business in India. We offer the best quality ERP software that is specially designed to cater to the needs of the manufacturing industry. It has multiple functionalities, which include cost reduction, operational efficiency, and faster decisions. Share your requirements today to get the top-notch ERP software solutions for your business.

#best erp for small manufacturing business in india#cloud erp software for manufacturing industry ahmedabad#cloud erp software for manufacturing business in india

0 notes

Text

Cut down waste, 📈 increase profits, and streamline operations in the hardware manufacturing industry with SAP Business One! 💡✨

#sap b1#cloud erp#sap erp#clouderp#sapbusinessone#sap business one#erp for small business#erp software#cloud partner#erpsolutions#hardware manufacturing

0 notes

Text

#technology#Enterprise Resource Planning (ERP)#ERP Solutions#Business Management Software#Integrated Business Applications#Supply Chain Management#Customer Relationship Management (CRM)#Financial Management Systems#Human Resources Management#Inventory Management Software#Manufacturing Resource Planning#Cloud ERP Solutions#On-Premise ERP Systems#ERP Implementation Services#ERP Consulting#ERP Software for Small Business#ERP Software for Manufacturing#ERP System Integration#ERP Software Development#ERP Customization Services#ERP Training and Support#technews#techcore

0 notes

Text

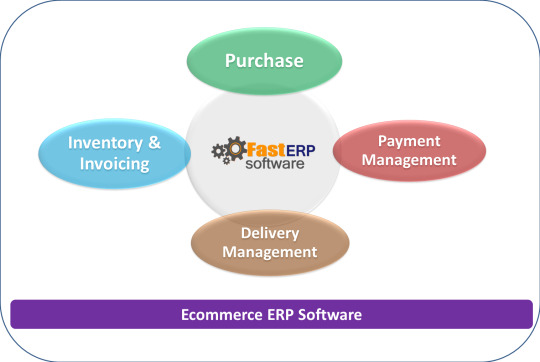

Future-Proofing Your Business: Fast ERP Software's Path to Success

We provide integrated ERP Software for Retail, Distribution and Manufacturing to thousands of customers to date, helping them to meet their business goals. ERP solutions developed by Fast ERP software are characterised by their flexibility and scalability to aid in the business growth of the customers in the time ahead. Cost-effective solutions are designed for specific needs and verticals, help mid-sized to large business ventures address issues, review business performances, and assist strategic decisions to fulfil the demands of the market.

ERP computer software stands for enterprise resource planning, but what does ERP mean? The simplest way to define ERP is to think about all the core business processes needed to run a company: finance, HR, manufacturing, supply chain, services, procurement, and others. At its most basic level, ERP helps in efficiently manage all processes in an integrated system. It is often referred to as the system of record of the organisation.

Importance of Enterprise Resource Planning (ERP) software- we provide The best web-based ERP solutions software in India, serve enterprise resource management and offer for managing core functions such as finance, human resources, supply chain, manufacturing, and customer relationship management. By consolidating data and processes into a centralised system, ERP enables organisations to break down silos, improve collaboration, and gain real-time insights into their operations.

Utilities- need to constantly review their capital assets, not only to meet the demand for future services but also for the replacement of ageing assets. Without ERP, the effort to prioritise these major asset investments would be difficult and error-prone. ERP also helps solve another critical utility company issue: forecasting of spare parts. Not having the right parts during an outage can create a significant customer service issue.

Wholesalers- importers, direct store delivery, and 3PL/4PL firms, on-time delivery. All organisations want to reduce distribution costs, increase inventory turns, and shorten order-to-cash time.

Manufacturers- ERP is manufacturing software for small businesses and supply chain systems to meet product quality goals, manage asset utilisation, control overtime costs and handle customer returns and money.

Service companies – including accounting, tax, engineering, IT, legal, and other professional services firms – require powerful, real-time mobile ERP computer software to balance service delivery commitments with financial health.

Enhancing Visibility and Control: increasing visibility and control over business operations. In real-time access to data and analytics, track project progress, and identify areas for improvement. It facilitates, monitoring cash flow, analysing sales trends, or forecasting demand, ERP computer software gives you details needed to make decisions and respond to changing market conditions. By installing security protocols and access controls, ERP safeguards confidential information.

Growth and Innovation: ERP enables businesses to innovate by providing a flexible platform for evolving market trends and customer demands. ERP supports strategic initiatives that yield growth and profitability. with cloud-based ERP solutions, businesses can access the latest features and able to grow in the dynamic business environment.

ERP software emerges as a strategic partner for your business growth. integrating core functions, streamlining operations, and providing actionable insights. ERP empowers organisations to optimise performance, mitigate risks, and seize new opportunities. small startup or a global enterprise, with ERP you will gain long-term benefits and propel your business towards success in the digital age.

#manufacturing erp software#best web based erp software in india#manufacturing software for small business

0 notes